Products Guitar Gallery Main Menu

|

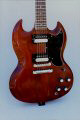

Gibson Sunburst Introduction A sunburst finish is one of the most daunting finishes for novices. However, the difficulty lies not so much in the application but in the blending of the colors required.... Along with a step by step description of the application this discussion is meant to offer solutions which will eliminate the difficulty of blending sunburst colors. With sunbursting, the devil really is in the details. The guitar that was used to prove the application and dye colors was a 1953 Gibson L-4. Two other period Gibsons were also used to compare the developing finish application and colors to the original finish. These two instruments were a 1946 J-45 and a 1951 CF100. After refinishing the L-4 also favorably compared to a 1930's L-7. (Early Gibson "bursts" sometimes appear darker than the post war instruments. This may be due to the yellowing of the lacquer coats). In all cases the "new" colors appeared to be a good match. The L-4 when received had been carelessly stripped with no attempt to protect the areas not being stripped. Signs of stripping splashover showed on the otherwise unabused neck and the interior was full of dried steel wool/stripper/stain "goop". The label was covered with old stripping residue. The body had been brush painted with a pinkish yellow varnish stain. The "restorer" as a crowning gesture signed his work by scratching his initials on the tailpiece. Using the methods discussed in Reranch 101 the body was taken back to a clean starting point. The interior was cleaned by using cotton swabs dipped in lacquer reducer and held with a set of medical type forceps. The label was also cleaned in this manner. Surprisingly the stamping ink was not affected by the reducer. After cleaning, a small ebony sanding block was used to lightly sand away any remaining stain. The block (apx. 3"x1"x3/8") as used has three flat washers glued to the top. Adhesive sand paper is attached to the sanding surface. The block is then dropped through the "f" sound hole and worked by hooking a 1/4"x12" section of copper tubing into one of the washers. The tubing can be bent to reach normally inaccessible areas. After sanding the interior, any remaining stain spots were brushed with bleach to remove. Water spots were also noticeable on the back. These were also bleached to remove. With the instrument ready for finishing the colors were then blended. The amber dye color decided upon was water based and wiped over the complete top. The burst is a bright yellow/red with the red color appearing as leaning to maroon or mahogany. The yellow is very evident also. The color shading and dark edge colors appear to be the same color applied in escalating darkness. Using the same color for shading and for opaquing the edge on the area of the L-4 did not offer satisfactory results. The shading color was correct but the edge color appeared as a dark mahogany with not enough black. The top was restripped and another approach was used. This approach required three dye colors rather than just two. With the amber and transition colors correct, adjustments were made in the edge color by adding a black component. The next section details the successful application. The instrument was protected as discussed in Reranch before coloring was begun. The amber dye used is water based and our part # GRAMBW. The dye was dissolved with 1/4 tsp. dye stirred into 8oz. liquid measure of water. The dye should be allowed to dissolve for at least three hours. (Be sure to first read Reranch before proceeding. Many steps and cautions against missteps are more fully discussed). On the L-4 the dye was wiped on in two passes and left to dry. (As noted prewar bursts sometimes appear darker. Additional amber passes will darken the burst area). The amber was then sealed by spraying two coats of 6 parts reducer to 1 part lacquer. If there are any dust particles in the sealer coats, after drying overnight the sealer coat can be lightly wet sanded. When sanding on very thin coats, using a grade coarser than #800 can be risky. The sealed finish was then sprayed with two coats of the normal reduction of 1 part reducer to 1 part clear lacquer. After drying overnight, the finish was carefully wet sanded with #400, followed by #600 and #800 grade paper. The next color applied was the shading color which forms the transition between the amber center and the near black edge area. Our # GRMBL, Medium Brown dye was used to shade the transtion area. The dye was first mixed by adding a 1/4tsp.to 8oz. of lacquer reducer. This solution, after dissolved, was then mixed 1 to 1 in a solution of 6 parts reducer to 1 part lacquer. The guitar was placed in a horizontal position to spray. The gun was set to vertical fan and the spray volume set to medium. A wet spray at this stage is to be avoided. The pressure was 20psi. If your gun will not spray smoothly at this pressure a higher pressure can be used. The top was sprayed with the verticle fan spraying away from the center. The goal is to not to spray any mahogany onto the bright amber center. The edges were sprayed first with subsequent passes moving closer to the amber. The passes should be allowed to dry to touch between passes. (Check often to be sure the color is being equally applied). As the edge darkens, a shaded zone about 1" to1 1/2" wide will appear between the dark edge and the unsprayed amber. This zone will move further from the edge and more toward the center of the guitar as more color is applied. The Gibson sunburst pattern can be described as appearing pear shaped with the upper bouts and lower bout edges very dark. Some shaded amber should show on the away-from-center side of the "f" holes. The body of the "pear" is amber with reddish (mahogany) shading. Once the mahogany shading zone matches the ideal, the edge color is ready to be applied. The

dark edge color is from the multiple passes of the Medium Brown dye. In

appling the edge color the fan should start at the edge and be sprayed

away from the center. A dark line will begin to appear at the edge and

as more spray is applied the edge zone will darken and the dark line will

move into the transitional shading. When the dark to reddish mahogany shading

transition appears correct, the edge area and upper bouts can be darkened

to near black. For the final darkening of the L-4, the gun setting was

changed from a fan to a small circle. Repetitive edge/upper bout passes

were made with the gun pointed away from the center at a near horizontal

angle. The edge color will appear black under normal light. Under bright

light it appears dark mahogany. When dry the surface may appear rough. Analine dyes when sprayed in a thin lacquer solution (as in this application) will darken without causing an unwanted lacquer build-up. But in a thin lacquer finish the black component in the dye will stand above the finer amber and mahogany components. Until sealed, the black component is vulnerable. But to your advantage, if the black line appears to be sprayed too far into the mahogany shading or if the black pattern is not symmetrical, the line can be corrected by dry wiping. A dry cotton cloth can be used but you may find that a finger tip can also be used to fine tune and blend the dark line. The black component will dissolve into the finish and flatten as the sealing and finishing coats are applied. If the pattern appears correct it is now ready for sealing and final finish coats. Return to Reranch for the final clear coats. |

|

| Fender Custom Colors | Gibson Specialty Colors | Wood Dye Colors | Clear Coats & Tints |

| Sunbursting Products | Finishing Supplies | ReRanch Custom Colors | Privacy Policy |

| BASIC FINISHING | GALLERY | PRODUCTS | MAIN MENU |